Komugi optimises load-capacity balancing to boost your profitability !

An APS solution designed for industrial SMEs that produce small and medium-sized batches (and unfortunately face delays !).

In 30 days, regain control of production of your order book.

Your Excel capacity analysis doesn't allow you to adjust your capacity and deliver to your customers on time ?

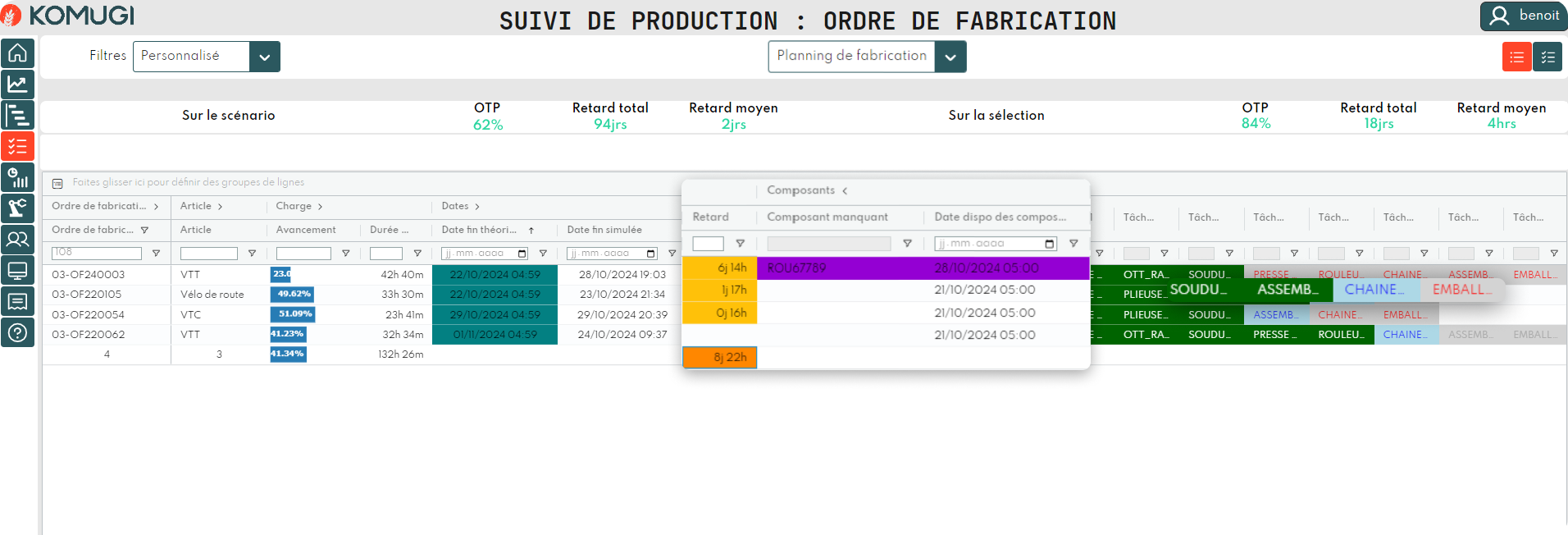

You suffer your bottlenecks in production, without seeing them coming or controlling them.

Your capacity adjustment actions are taken blindly or based on trends.

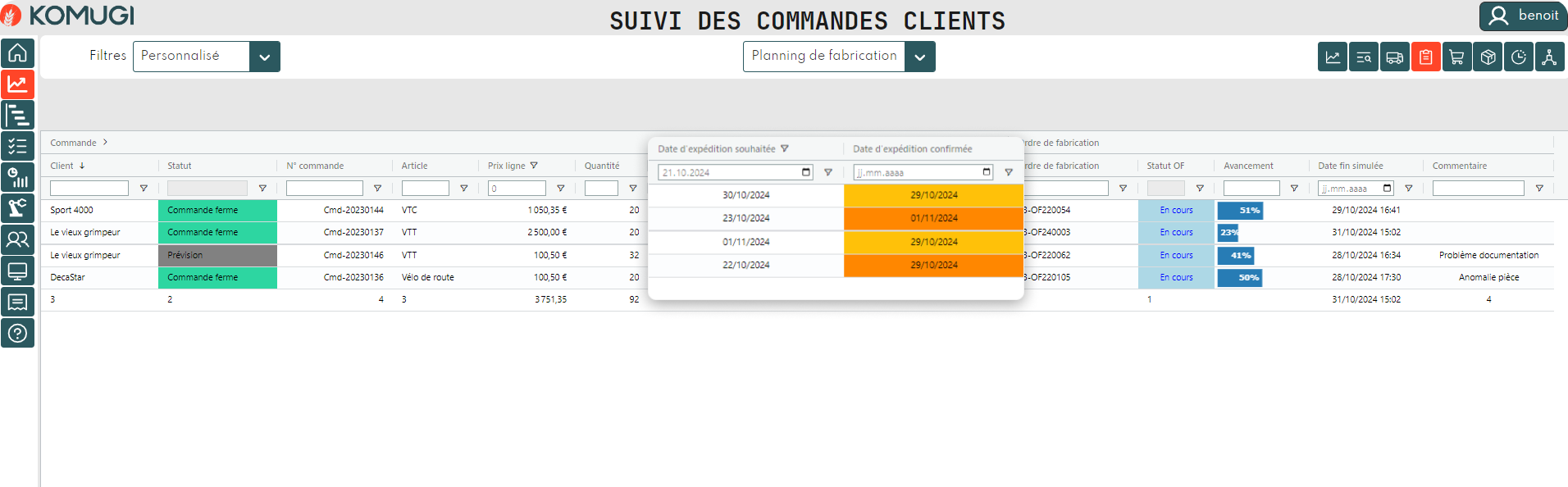

Your customers are being delivered late and you find out at the last minute!

Find out how capacity load matching can to improve your plant's operating results

- Confirm the exact lead times for each order in 1 click using Komugi's calculation.

- Arbitrate your manufacturing scenarios according to QCD (Quality-Cost-Delivery) criteria.

- Monitor schedule adherence, detect the impact of unforeseen events, avoid nasty surprises for your customers and restore peace of mind in the workshop.

Testimonials

Intégrations :

Komugi operates in the following sectors...

FAQ

APS software is a tool used in production and supply chain management. It helps companies to plan and schedule their operations more efficiently, taking into account factors such as available resources, lead times, production constraints and customer demand.

The main objectives of APS software include :

- Resource optimisation: Maximising the use of machines and employees.

- Reducing lead times: Minimising the time needed to produce and deliver products.

- Improved flexibility: Adapt quickly to changes in demand or production interruptions.

- Increased visibility: Provide an overview of sales, production and stocks for better decision-making.

These tools are particularly useful in sectors such as manufacturing, where accurate planning is crucial to competitiveness.

The answer is in the data horizon:

ERPs manage accounting data; they look to the past and record the life of the company up to the present day (invoice date, production date, etc.). ERP systems make it possible to find out the turnover or profit and loss account for previous months.

Komugi, on the other hand, is resolutely forward-looking, translating operational production or business data (sales forecasts, etc.) into actionable financial forecasts.

Komugi can be used to forecast the end-of-month landing, expenditure and consumption of raw materials or the number of hours of temporary staff over the next few weeks.

An APS and an MES are two types of software used in the management of production operations, but they have distinct objectives and functionalities:

The objective of APS is to focus on the planning and scheduling of operations. It aims to optimise the use of resources, meet deadlines and manage production priorities.

The objective of the MES is to focus on the execution of manufacturing operations in real time. It collects data, monitors processes and controls operations in the field.

Komugi software plans small and medium-sized batch production runs for SMEs.

APS software requirements :

- Improve the profitability of my production

- Sizing my workforce requirements

- Project my turnover, costs and inventory value

- Draw up optimised schedules over different horizons

- Meet my customer deadlines

- Make decisions based on figures

- Anticipate material shortages and bottlenecks

- Be responsive to constraints

Requirements for MES software :

- Ensure production traceability

- Monitor non-conformities and rejects in production

- Record my production times

- Be alerted when a machine breaks down

- Ensure that the production schedule is followed

- Reduced production times: by optimising schedules and making them more reliable, as well as minimising downtime throughout the production chain.

- Increased flexibility: Komugi makes it possible to quickly adjust schedules in response to changing priorities or unforeseen circumstances.

- Optimisation of resources: better allocation of resources (machines and operators) to avoid overloads or under-utilisation.

- Improved overall performance: with an overall view of scheduling, it becomes easier to identify bottlenecks and improve production flow.

Protecting your data is a priority for us, which is why our solution complies with the highest security standards and is in the process of obtaining ISO27001 and ISO27701 certification.

Yes, Komugi is software accessible via a web interface (SaaS), which means it can be used remotely from any device connected to the Internet, including computers, tablets and smartphones.

This accessibility allows production managers and planners to monitor and adjust schedules at any time, even away from the production site.